Roaches International Takes Fabric Evaluation Commercial

No two people will describe how a fabric looks and feels in the same way. The lack of a common language to describe fabric aesthetics poses challenges for communicating across the complex global fashion and textile supply chain.

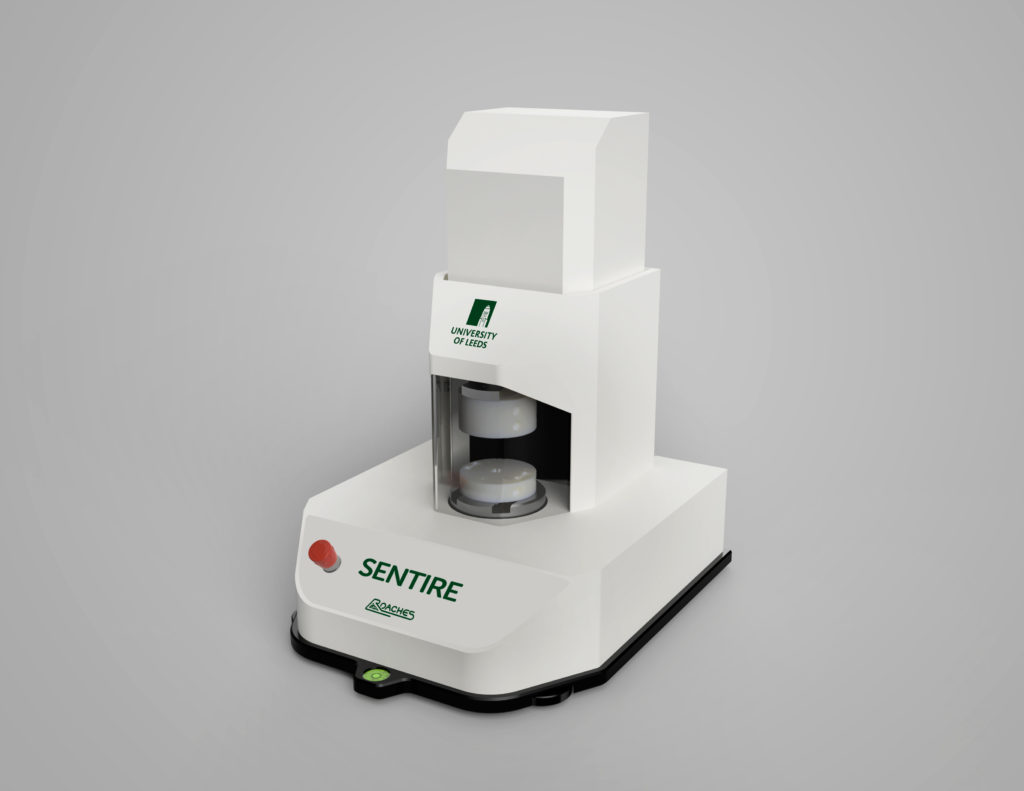

In a project funded by Future Fashion Factory, Roaches International is working with University of Leeds researchers to commercialise research on fabric evaluation and analysis, creating a fabric evaluation system that removes subjectivity and ensures consistency in measuring fabric tactile properties.

One of the biggest challenges faced by designers and manufacturers is describing and sharing information about fabric aesthetics before the physical fabrics are made, or without the costly and time-consuming process of transporting physical samples. The dramatic reduction in travel caused by Covid-19 has highlighted and made these issues even more acute.

Without any standard language to quantitatively describe a fabric’s tactile properties, it is difficult to ensure consistently high quality in fashion products, leading to higher levels of waste and environmental impacts.

Researchers at the University of Leeds have been developing new technologies to solve this challenge. The team at Roaches International partnered with Professor Ningtao Mao at the University of Leeds, who leads the development of the Leeds University Fabric Handle Evaluation System (LUFHES).

“We are aware of the long term challenge which exists in communicating touch-feel of fabrics within textile, fashion and retailing industries. The LUFHES technology is intended to define fabric tactile properties in a haptic spatial system, similar to how colour charts have been digitally defined for colour palettes, and Tog value defined for warmness/coolness,” said Professor Mao.

Fabric samples are placed into LUFHES that then runs a series of tests to generate quantitative fabric tactile property data akin to a fingerprint for the fabric, which can then be compared against other samples and communicated digitally to partner in different locations.

Working closely with Professor Mao and potential end users, Roaches International led a collaborative innovation project to develop LUFHES’ technology into a commercial product. Supported in Future Fashion Factory’s first funding call, it focused on refining the sampling method, the fabric evaluation system itself, and user-operated software.

Reliable and consistent sampling is crucial to ensure the quality of the generated data. Roaches International created a device that would automate the process, ultimately building a more efficient system for business use.

The fabric evaluation system consisted of two parts – the automated measuring device itself, with a casing suitable for industrial settings based on commercially available materials, and software to control the system and algorithm for data processing.

Professor Mao has worked on-site at Roaches International to support the project, as well as being in frequent contact with the software developer.

Roaches International is about to begin evaluating the pre-production prototype, completing the initial performance tests and planning the commercialization process. The team plans to work with clients to either access their fabric archive to generate valuable data for their fabric designs, or to help their technical team to gauge the customized touch feel of their fabric finishes.

From there, Roaches International can focus on testing the system with partners in the fashion and textile supply chain, evaluating how well the data obtained can be used to help the communication of the fabric qualities of their fashion products in a different location. To achieve this the company will build additional units.

“From our first introduction to LUFHES we could see the possibilities for this technology to impact the supply chain in a similar way the spectrophotometer did for the communication of colour,” said Sean O’Neill, Roaches International Managing Director.

“LUFHES is an ideal addition to Roaches International offering and fits perfectly with our ambitions to designing and supplying apparatus with a higher level of technology.”

The product will have significant benefits for Roaches International’s clients, shortening lead times, ensuring the consistency and quality of products as well as developing fabrics having a customised touch feel for specific fashion products. By reducing waste in the supply chain, generated when products do not meet performance requirements and quality standards, it will also contribute to the long-term sustainability of the fashion industry.

The company is even considering the system’s applications in e-commerce, working with brands and retailers to improve the online customer experience – a host of tangible commercial benefits born from this groundbreaking research.